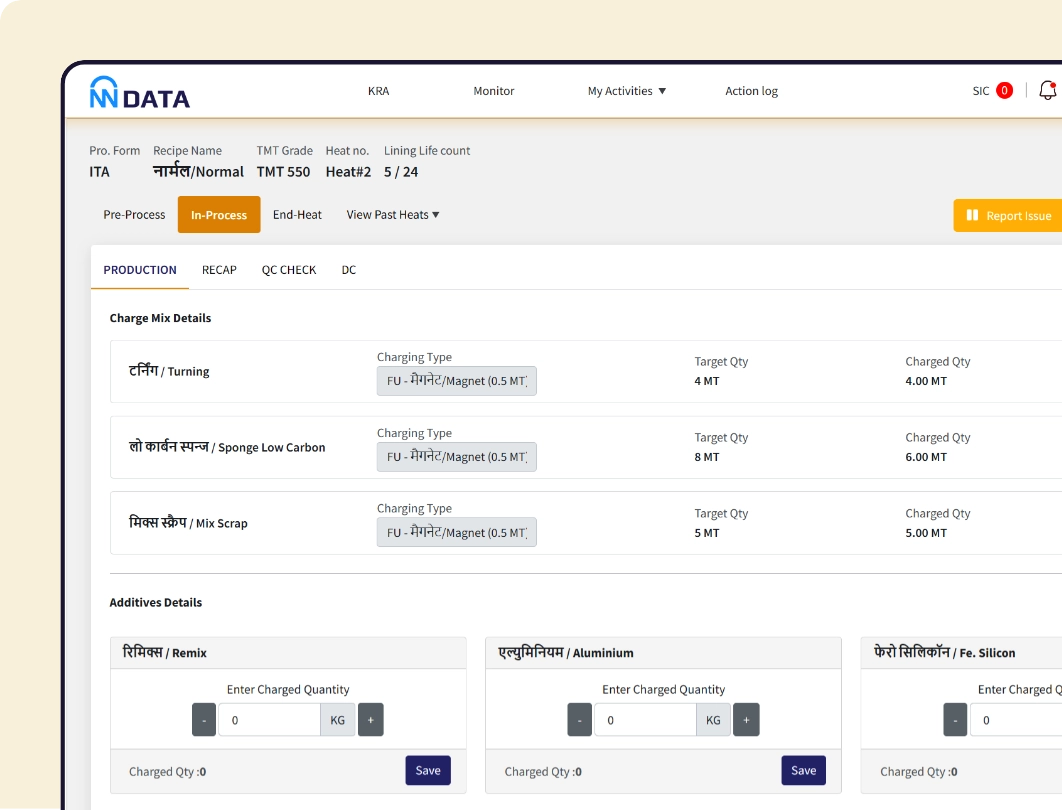

Connect DATA

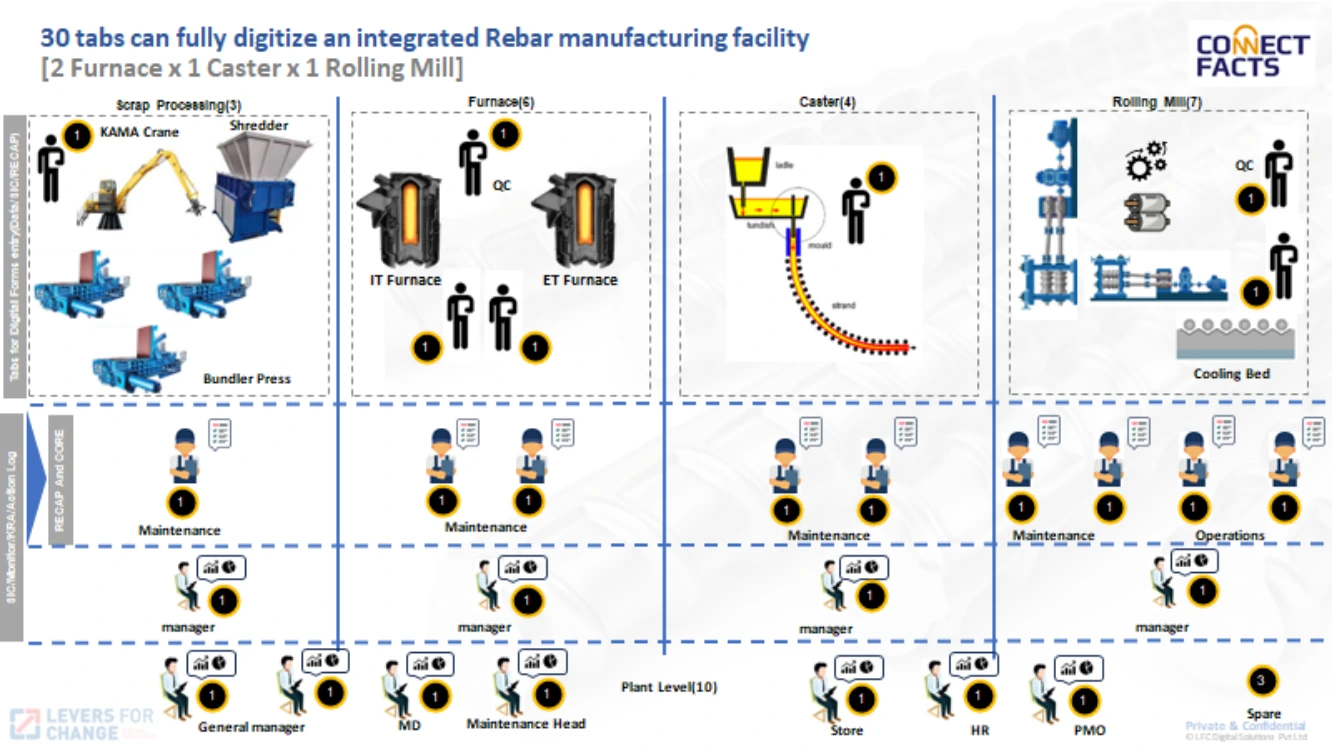

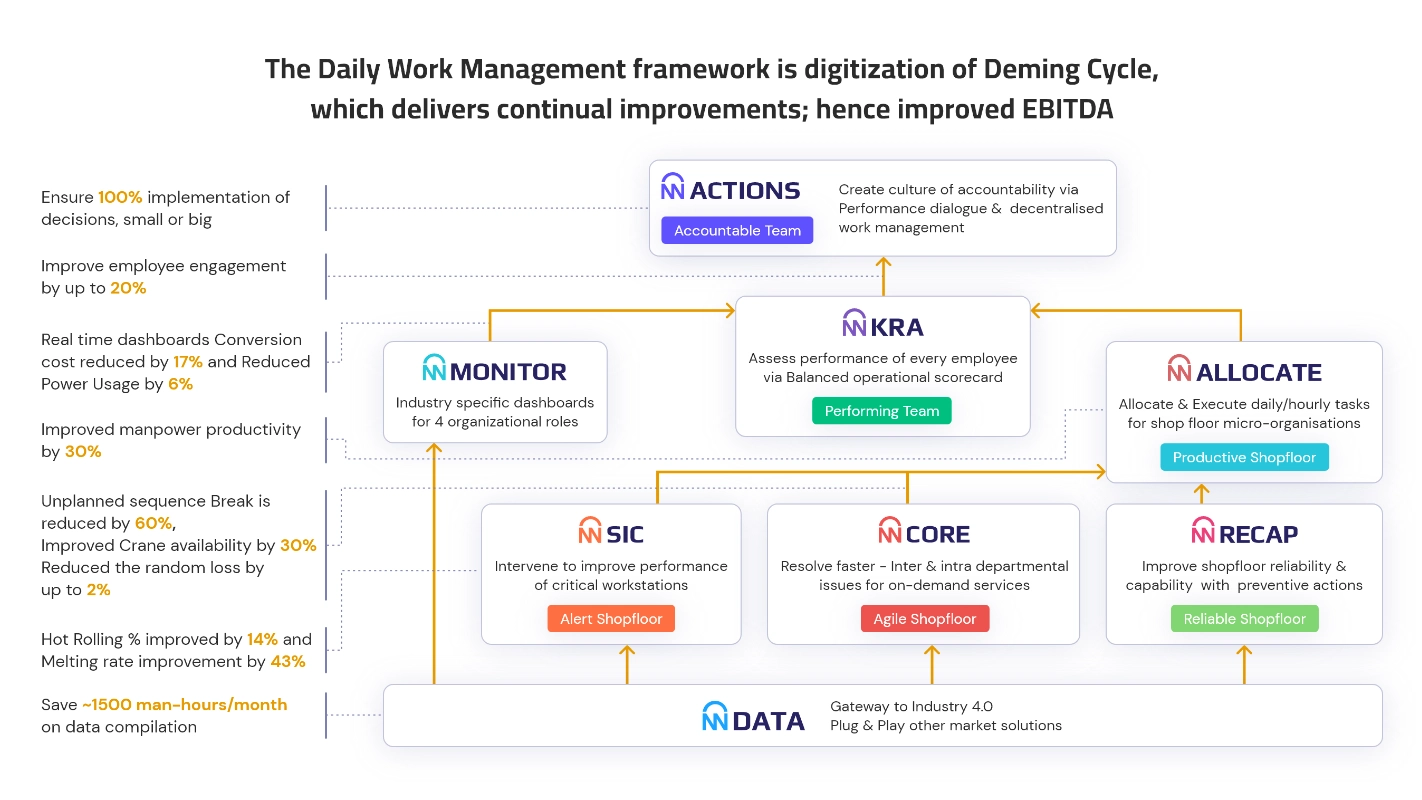

The gateway to Industry 4.0, this application is your single source of data for end-to-end production operations. Digitize data through simple forms and integrate data from multiple digital systems to a single source (ERP, PLC, Scada, Sensors). As the virtual twin of your production process, it enables easy data contextualization. Plug and use any related analytics or workflow automation solutions seamlessly.

As the 100% digital twin, the application includes a:

- Complete holistic data map

- Exhaustive database

Know More

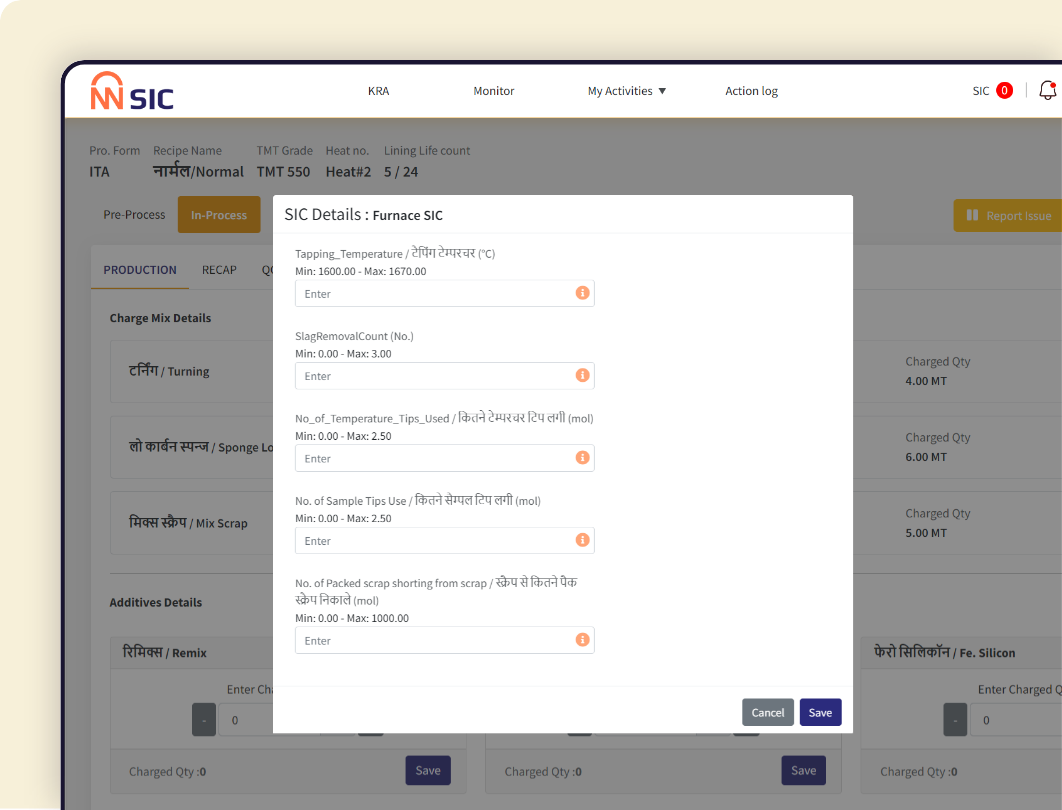

Connect SIC

Intervene on time to improve the performance of critical workstations. SIC is an active supervision tool that minimizes performance leakage on the shop floor that are due controllable causes. It monitors the singular critical parameter impacting throughput or quality and initiates an intervention and escalation mechanism to attend to issues on time. With SIC, you get customized workflows and KPIs for the TMT industry.

With easy tracking of target v/s actual figures, you can:

- Improve throughput by 15-20%

- Reduced unplanned breaks by 60%

Know More

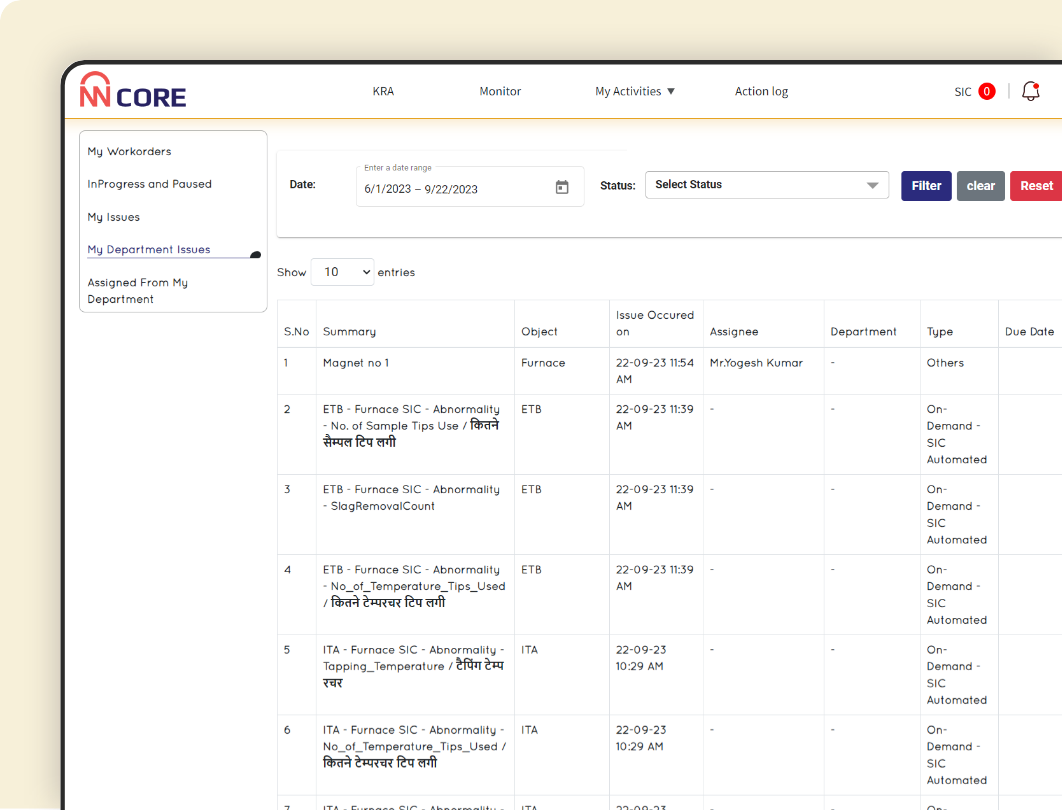

Connect CORE

Coordinate and resolve inter and intra departmental issues for on-demand services. The application provides an automated workflow for identified inter-departmental coordination activities that potentially impact availability or performance. Simple digital signals and a live messaging system lets you raise requests, measure service levels, auto-allocate tasks, and track them for closure.

Utilize the swift communication system and custom workflows to:

- Improve ladle availability by 25%

- Reduce availability losses by 10-15%

Know More

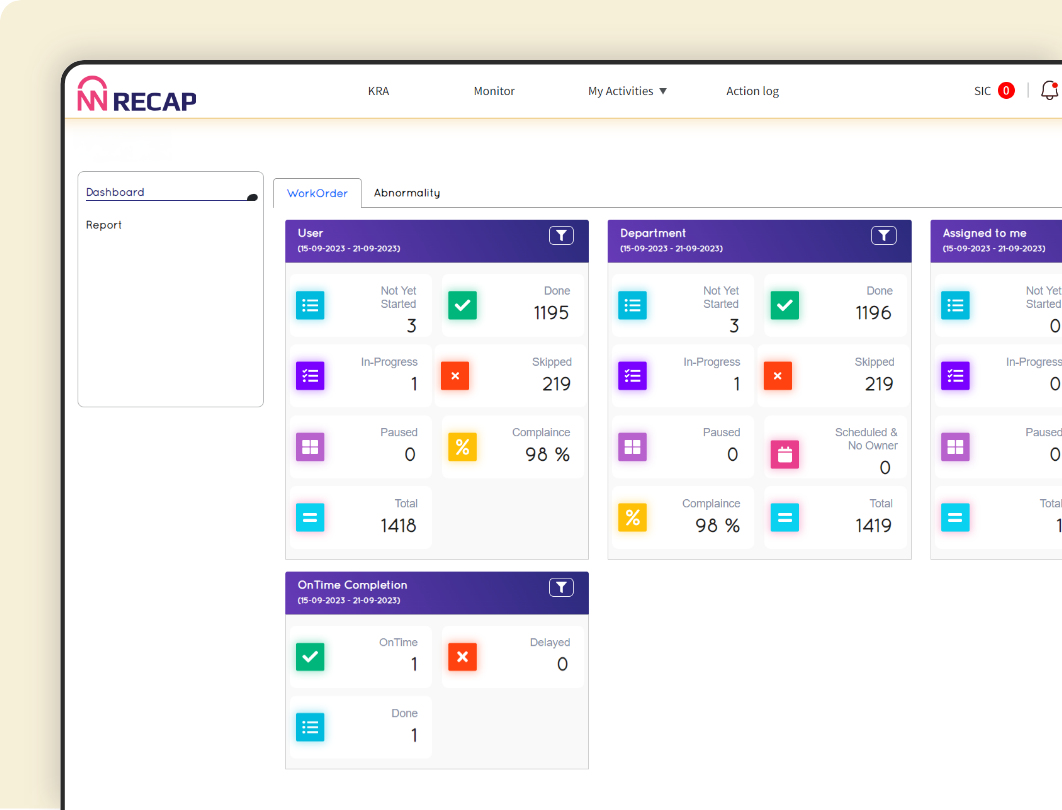

Connect RECAP

Improve shop floor reliability and capability with well-organized scheduled and preventive maintenance activities. Calendarized workflows bring rigor and effectiveness for all manually practiced preventive systems on a shop floor like process parameter checks. The proof of compliance is made simple with an

auto-ticketing system for easy tracking, resolution, and closure of abnormalities from each checklist.

Use tailored preventive system with specific KPIs to:

- Ensure day on day task completing

- Increase furnace lining life by 22%

Know More

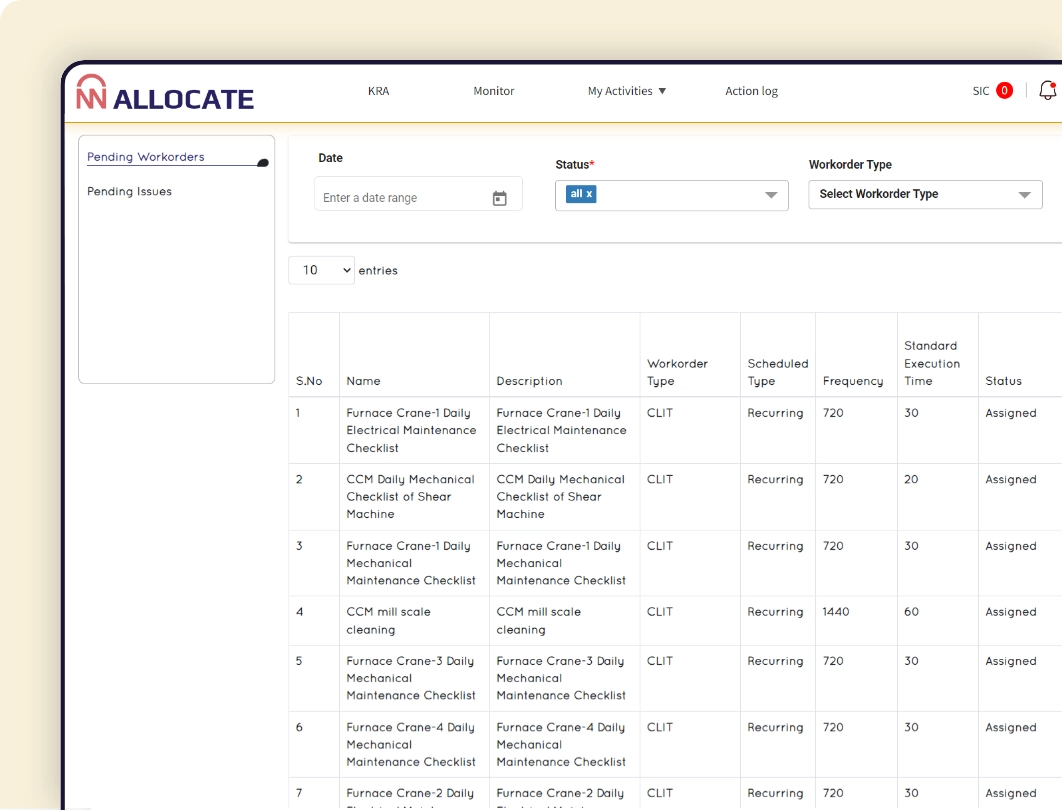

Connect ALLOCATE

Allocate and execute daily/hourly tasks for shop floor micro-organizations and ensure quick problem resolution. Present detailed shop floor information in the form of photos and videos within and across teams. Managers in the production, maintenance, roll mill, and other departments can easily assign inter and intra departmental tasks.

Resolve issues arising from scheduled activities to:

- Increase equipment availability by 10%

- Improve team utilization by 20%

Know More

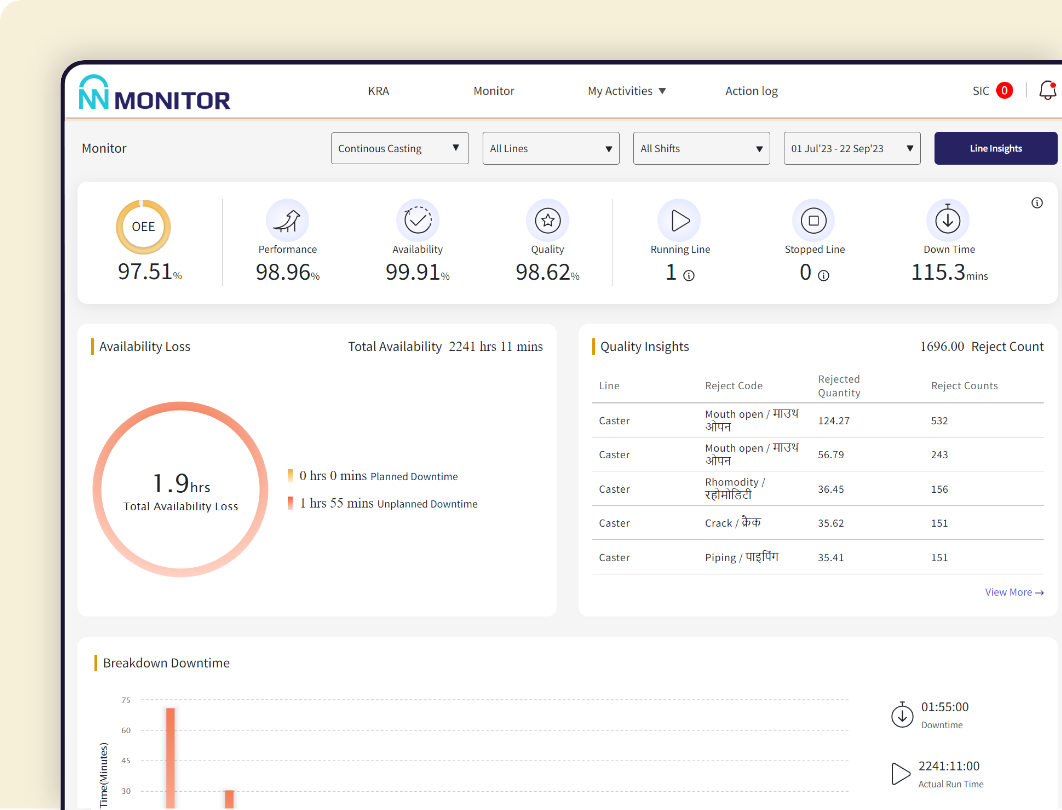

Connect MONITOR

Get industry specific KPI dashboards for 4 organizational roles including operators, supervisors, managers, and leaders. Make the most of a real-time dashboard that showcases only limited and relevant performance data and KPIs for each role. The customizable KPI dashboard improves awareness and facilitates immediate interventions as well as corrective actions for performance improvements.

Utilize the relevant and meaningful data insights to:

- Improve overall productivity by 15 to 35%

- Get better manpower presence across teams

Know More

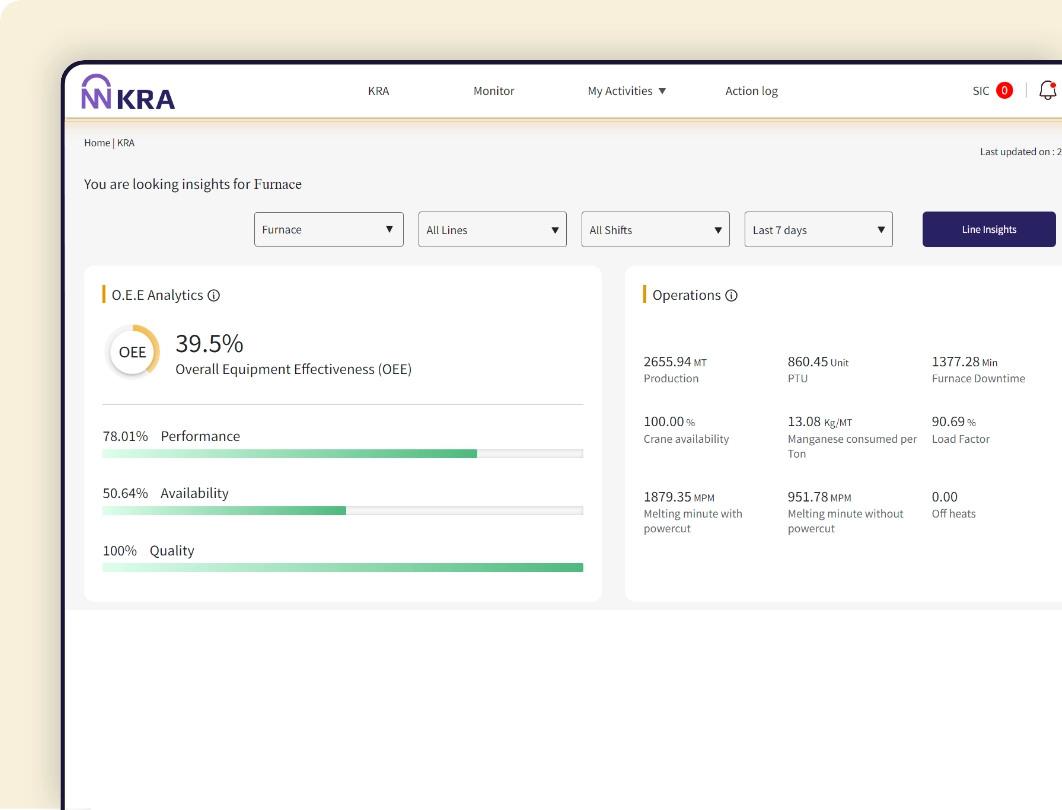

Connect KRA

Benefit from a real-time balanced scorecard for every role of the shop floor organization including material procurement, scrap processing, melting, casting, rolling, maintenance, quality, and more. Each KRA dashboard is customized. This application provides a 360° view of performance, increases awareness amongst employees, and enables better engagement, thereby establishing a continuous feedback loop.

Make the most of defined KRA bands and KPI dashboards to:

- Enhance real-time performance

- Track actuals v/s target numbers

Know More

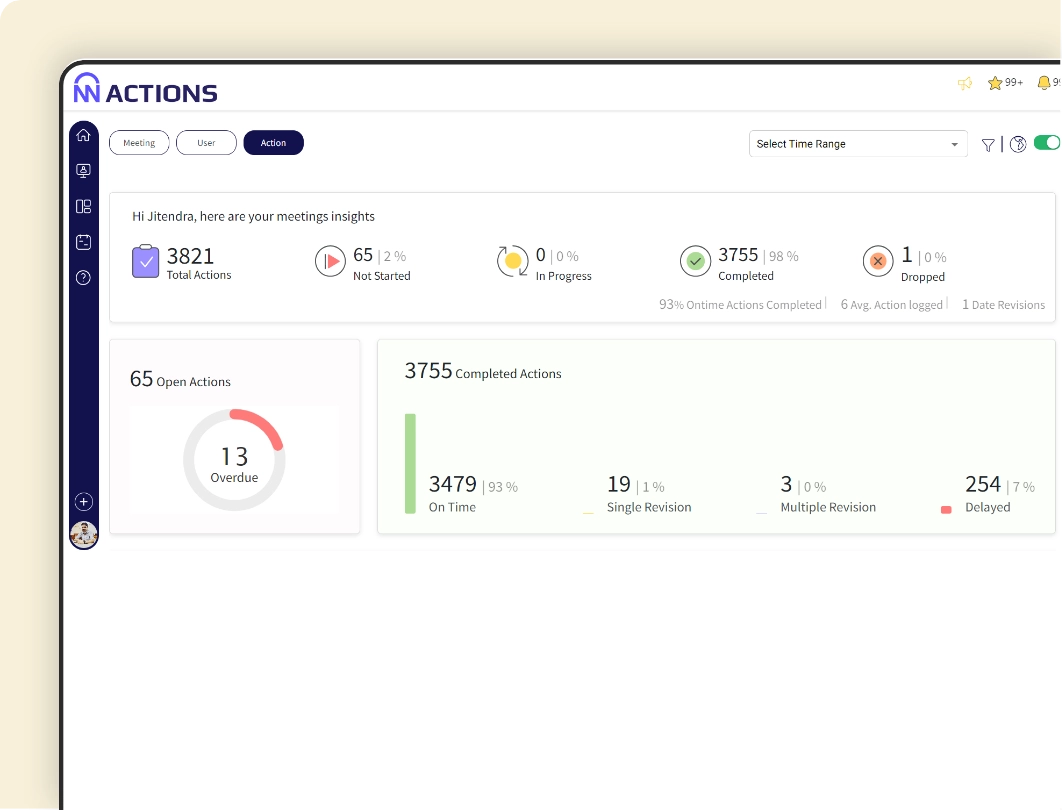

Connect ACTIONS

Review meetings are the real gemba for managers and leaders. With Connect ACTIONS, you can build a 3-tier performance dialogue system, calendarize review meetings, conduct effective reviews, log all actions, and track them till closure. Effective meeting management can improve accountability for performance in the short term and build a culture of continuous improvement in the long term.

Connect ACTIONS improves productivity with:

- Automatic meeting scores for punctuality and efficiency

- Detailed tracking including current status and allocations

Know More