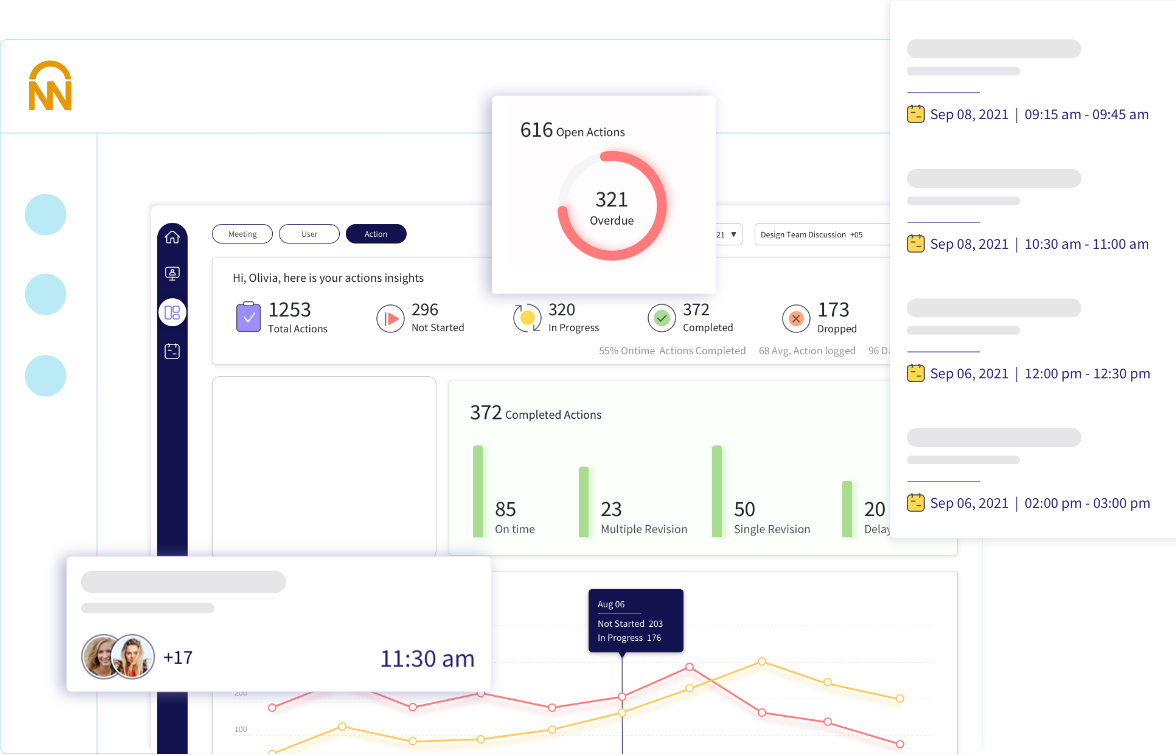

Enable faster data-driven decision making and resolution to issues. Extend digital workflow to all levels of shop floor (operator to manager) for improved coordination and resolution of issues. Invest in your factory workers and unlock their potential now with the right data and optimize productive time.

Continuous flow of information for improved productive time

Structured process for improvement strategies

On demand collaboration for data driven problem resolution

Digital trail of historical issues & resolution for shop floor asset

Visibility for trends to identify improvement areas

Progressive monitoring by maximizing automation

It helps issue identification, ticketing and resolution tracking to significantly improve service levels and accountability within the factory. Digitization of standard workflows for a factory floor enables:

Responsive manufacturing is the process of addressing challenges on the factory floor and enabling manufacturing workers to follow an agile, predictive and corrective process. By responding to critical issues on time, it helps reduce the cost of production by removing shadow expenses.

In any factory, predictive and corrective maintenance are essential to keeping the production line running smoothly. Predictive maintenance is the practice of using data to anticipate when an issue is likely to occur, so that it can be fixed before it causes a problem. Corrective maintenance, on the other hand, is the practice of fixing an issue after it has already caused a problem.

Both approaches have their advantages and disadvantages. Predictive maintenance can help to avoid downtime, but it requires accurate data and can be expensive to implement. Corrective maintenance is less expensive and can be faster, but it often leads to disruptions in production. Having a smooth solution with Connect CORE solution will facilitate the factory floor with accurate predictive and corrective maintenance.