Revolutionize the overall management of your factory with an advanced Connect MONITOR. Bring true value to your shop floor with actionable insights and active supervision.

Activate online OEE tracker for each process stage

Integrate with Connect DATA to facilitate smooth data flow

Gain insights to understand normal & bottleneck operations

Bring healthy peer competition with Connect MONITOR

Get responsive root cause analysis with digital gemba board

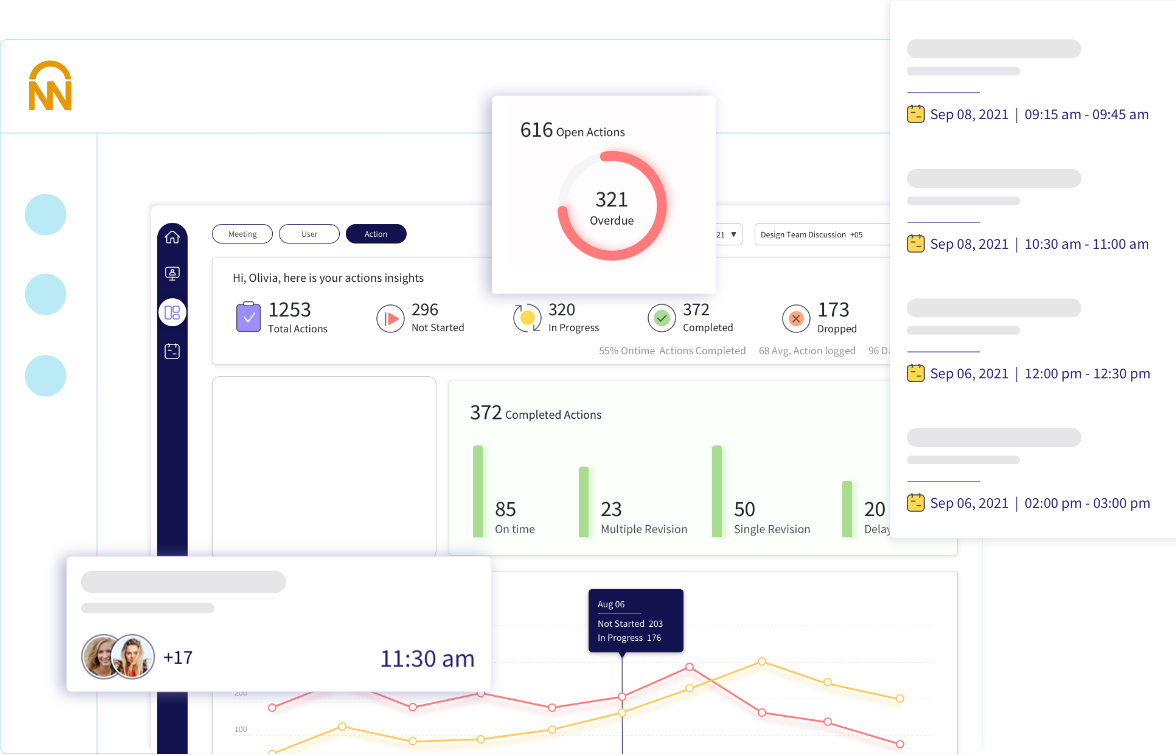

Simplify observability and view performance at a glance

Connect MONITOR means measurement of the performance over a span of time against key Performance Indicators. It is an activity done at length and needs to be accurate and consistent with validated data. It includes assessment of processing time, inspection time, move time and queue time amongst others.

Things that cannot be measured cannot be managed. Understand the relation between goals and action items on the production floor with performance indicators. These include availability, performance and quality - the three vital components of OEE. Other vital KPIs include manufacturing cycle time, behind plan, throughput, downtime and bottom line.

Yes, Connect MONITOR includes production monitoring and quality control. Production monitoring involves scrutinizing the factory floor, supervising and enforcing various requirements and identifying and eliminating defects. The end goal is to ensure high quality output with best ROI and minimum downtime.