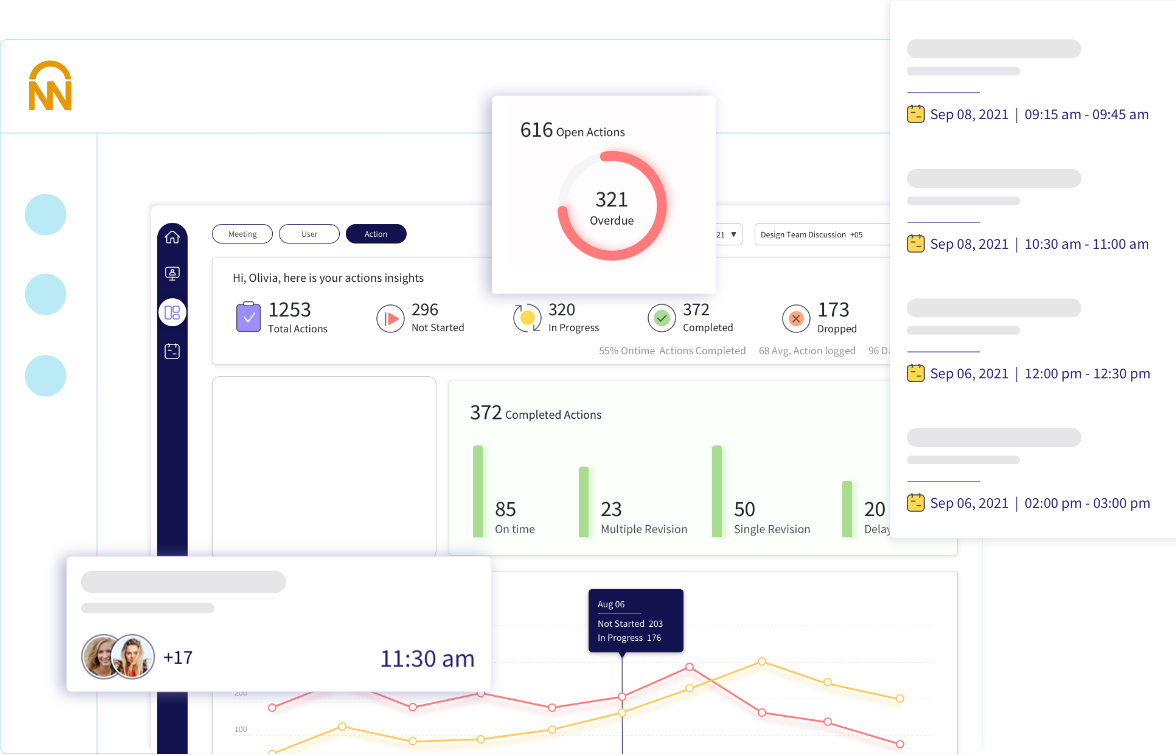

Connect SIC is a shop floor supervisory review and control mechanism, which can help to reduce downtime and improve production control. In addition, regular checks in shorter intervals can help to identify potential areas of improvement. Effective ongoing application of Connect SIC has the potential to eliminate bottleneck operations.

Methodical monitoring for performance optimization

Timely resolution of production line issues

Smooth identification of potential areas of improvement

Ability to look backward and forward periodically

Facilitate action items for holistic performance improvement

Encourage progress feedback against expectation

Connect SIC is a comprehensive management process that identifies and acts on various opportunities to bring in continuous improvement. With the end goal to improve efficiency and effectiveness of the shop floor, it facilitates employees to provide regular feedback against expected outcome pertaining to allotted tasks and prevent deviations in real-time.

The goal is to identify critical issues and establish the best timelines for machine intervention. It will depend on the number of issues, remediation process and targeted incremental improvements amongst others.

By understanding and evaluating performance, availability and quality at regular intervals, forecasting of risks and bringing attention to priority tasks is executed. This helps monitor and drive productivity improvements throughout the production shift.